SBFI North America's Solar System Cuts Energy Consumption to 25% in First Week

Executive Summary

When Zach Gilgen first stepped onto the SBFI North America’s campus in North Carolina, the potential was impossible to ignore. “Plenty of sunlight,” he recalled, “it just seemed like optimal conditions.” That initial impression planted a seed—one that eventually grew into a company-wide solar commitment aligned with SBFI’s ambitious “Road To 50” sustainability initiative.

SBFI designs and builds advanced technical furniture for mission-critical environments where people and technology come together—like control rooms, trading floors, and dispatch centers. Their workstations, desks, and monitor systems are engineered to support high-density technology setups while prioritizing user comfort, efficiency, and durability. With a focus on ergonomics, customization, and seamless tech integration, SBFI helps create workspaces where teams can perform at their best in high-pressure, technology-driven settings.

Zach, who serves as Procurement Manager for SBFI North America, recognized solar energy as a perfect match for their mission. He presented the idea to the leadership team as part of their “Green on Green” pitch—green for the environment, and green for the financial returns. The proposal quickly gained traction, thanks to its clear alignment with the company’s values and measurable environmental impact.

Project Background

For SBFI North America, going solar wasn’t just about adopting new technology to better the planet or save them money—it was about finding a trusted partner for the long term. The decision to work with Sugar Hollow Solar was heavily influenced by the positive experiences of previous clients, particularly Systems Logistics Vertique, a global manufacturer with a plant in the Western North Carolina area. After reviewing the metrics and glowing recommendations across review sites and in the community, it was clear that Sugar Hollow Solar stood out. With unanimous support from all stakeholders, SBFI chose Sugar Hollow, confident they would meet their energy goals while building a lasting partnership for the future.

“Every avenue that I was asking about—tax law, credits, system function, ROI—was explained,” Zach said. “I never felt like I was being sold more than we needed. If anything, it was the opposite. Sugar Hollow guided us through everything, and the education behind it was fantastic.”

Zach emphasized how critical it was to have a partner who could demystify the process for both leadership and facilities staff alike. From navigating tax incentives to understanding kilowatt-hours, Sugar Hollow became a trusted resource. “It wasn’t just about installing panels. It was about feeling confident in every decision along the way.”

Solar Solution Details

SBFI North America’s system features 258 Q CELLS 485-watt panels and Solar Edge Inverter (SE100K), totaling a capacity of 125.13 kilowatts (kW). This system size refers to the maximum power output the system can produce under ideal conditions, like peak sunlight, at a single moment in time.

To put this into perspective, a typical U.S. home solar system ranges from 5 to 10 kW. So this 125.13 kW commercial system is more than 10 times larger than a standard residential setup, designed to support the significant energy demands of a manufacturing facility like SBFI’s.

In a region like Western North Carolina, this system is expected to generate over 160,000 kilowatt-hours (kWh) of electricity annually, helping SBFI significantly offset its operational energy use while advancing its sustainability goals.

Additionally, the use of Q CELLS panels with domestic content helps safeguard the project from tariff-related risks and politically driven supply chain disruptions—an increasingly important consideration for companies making long-term infrastructure investments.

SBFI’s energy usage typically exceeds 200,000 kWh annually, driven by SBFI’s 24/5 manufacturing operations and the constant power demands of its facility. For a commercial utility customer in North Carolina, this level of consumption can translate to tens of thousands of dollars in annual electricity costs- a key factor when calculating ROI and payback timelines for solar investments. Reducing reliance on utility power with on-site solar is helping SBFI plan for more stable operating costs and long-term savings.

Measurable Results

SBFI’s 125.13 kW system was up and running in mid-March 2025, and within days, Zach saw the numbers he’d hoped for.

“Between Wednesday afternoon and Sunday, the system generated over 2,000 kilowatt hours,” Zach shared. “That nearly matched our building’s consumption for the same period. It was immediate, visible proof that this works.”

Financial ROI

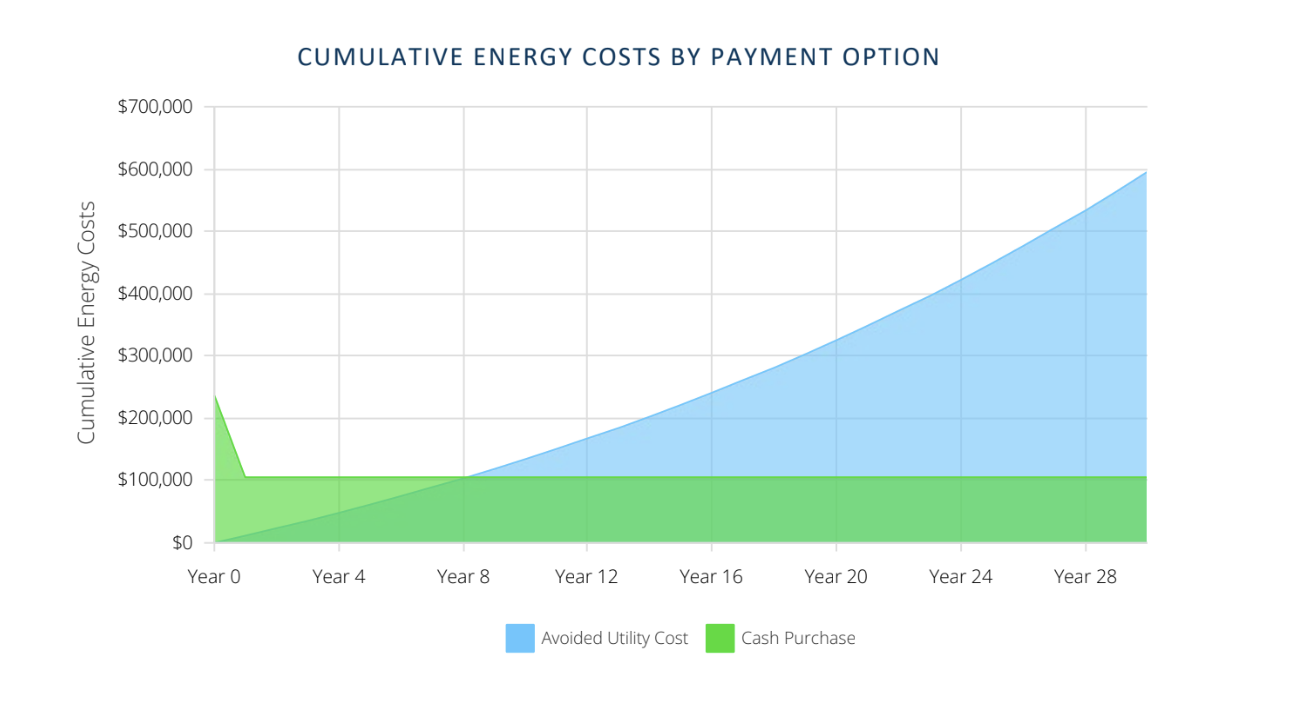

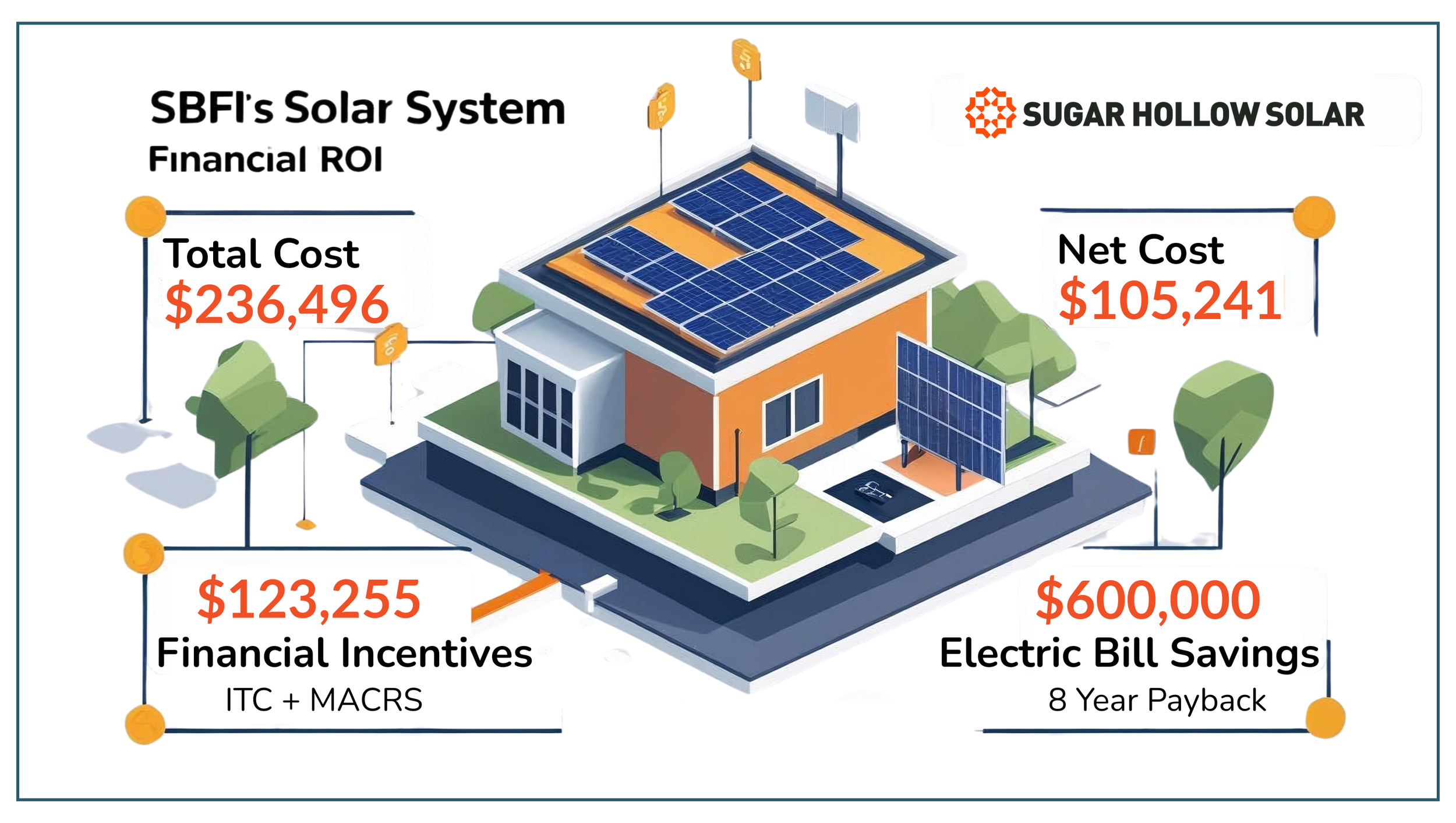

SBFI’s transition to solar was made even smarter by taking advantage of over $123,000 in incentives—including the Investment Tax Credit (ITC) and MACRS depreciation—which slashed their upfront cost nearly in half. With a net cost of just $105,241 and nearly $600,000 in projected electric bill savings, they’re on track to recoup their investment in just 8 years, often even sooner.

“The return on investment, if you want to talk financial numbers, is a small fraction of the lifespan that these solar cells have... your talk about a six-year, seven-year ROI. We have 17–18 additional years where you're offsetting energy costs. That's a heck of a gain right there. Then, when you switch over to the environmental aspects—the offset of carbon emissions—it’s just a win-win across the board.”

— Zach Gilgen, Procurement Manager at SBFI Group

Environmental Stats

Within just six weeks of being commissioned on March 25, 2025, SBFI’s solar system has already made a measurable impact. As of early May, the system has produced 25.81 megawatt-hours (MWh) of clean energy—an impressive start that demonstrates the power and potential of the installation.

This early production equates to the environmental benefit of:

305 trees planted

3.98 cars taken off the road

3.32 homes powered

20,217 pounds of coal avoided

And that’s just the beginning. Over the next 20 years, the system is projected to deliver even greater environmental returns. Using data from the EPA’s Greenhouse Gas Equivalencies Calculator, SBFI’s solar installation is expected to offset approximately:

2,640 tons of CO₂

The equivalent of 6 million miles driven by passenger vehicles

The environmental benefit of planting 39,595 trees

These numbers highlight how the decision to go solar aligns with SBFI’s broader sustainability goals—not only reducing operating costs, but also reinforcing their commitment to long-term environmental stewardship.

Strategic Goals Met

SBFI is now eyeing net-zero carbon emissions by 2030, and solar is a cornerstone of that journey. “Whatever helps us get to that goal, we’re considering. This project was a huge step,” Zach said. And the momentum is personal, too—he’s already talking with Sugar Hollow about adding solar to his own home.

His message to others considering solar? “The data is there. The benefits are proven. If you’re curious—even just a little—start by talking to Sugar Hollow. They’ll put you on the right path.”

“It’s real. It works. And having Sugar Hollow as a guide made all the difference. I’m not getting paid to say this—but yeah, start with Sugar Hollow.”

- Zach Gilgen, Procurement Manager at SBFI Group